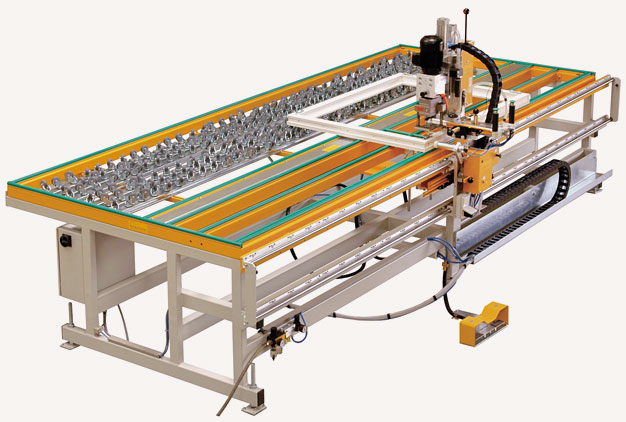

Frame assembly station RM 4000 (PDF)

For the automatic drilling and screwing of corner supports and scissor bearings. The transport of cladding frames occur manually, the fitting are placed manually.

Table-width 3000 mm; optional: 4000 mm

Depth 1630 mm

Table covered with sliding strips; optional: omni-wheels

Shaft double guide, L = 3200 mm, for the taking of drilling-, and screwing units for the processing of corner supports and scissors

![]()

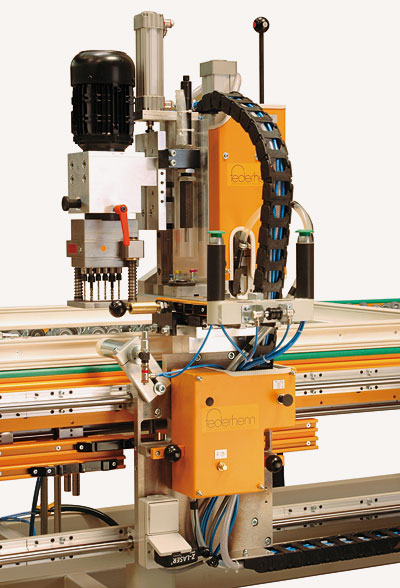

Two pneumatic fold stops that are lowerable below table height with a rotary turret for the exact positioning of two to four different frame construction depths

Frame Clamping- and Positioning installation, pneumatically adjustable through middle of the table. Designed for frame fold measurement from 360 to 2400 mm or 360 to 3200 mm

![]()

Options:

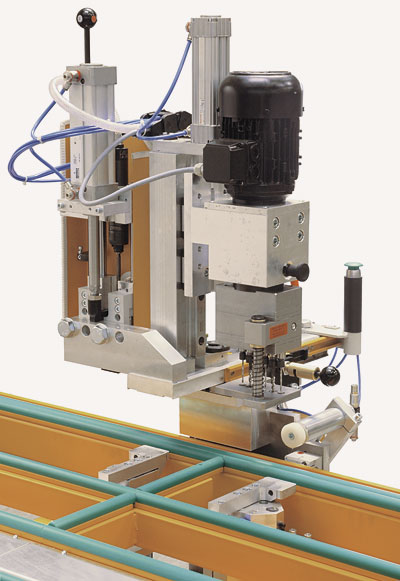

- Adjusting device with additional vertical screw feed unit in Y-direction for the screwing together of corner supports and scissors bearings on three- and multi-wing frames.

- Laser diode-module as line laser

- Turning direction manually 90° for a spindle lathe drill head for the drilling of corner supports and scissors bearings on three- and multi-wing frames